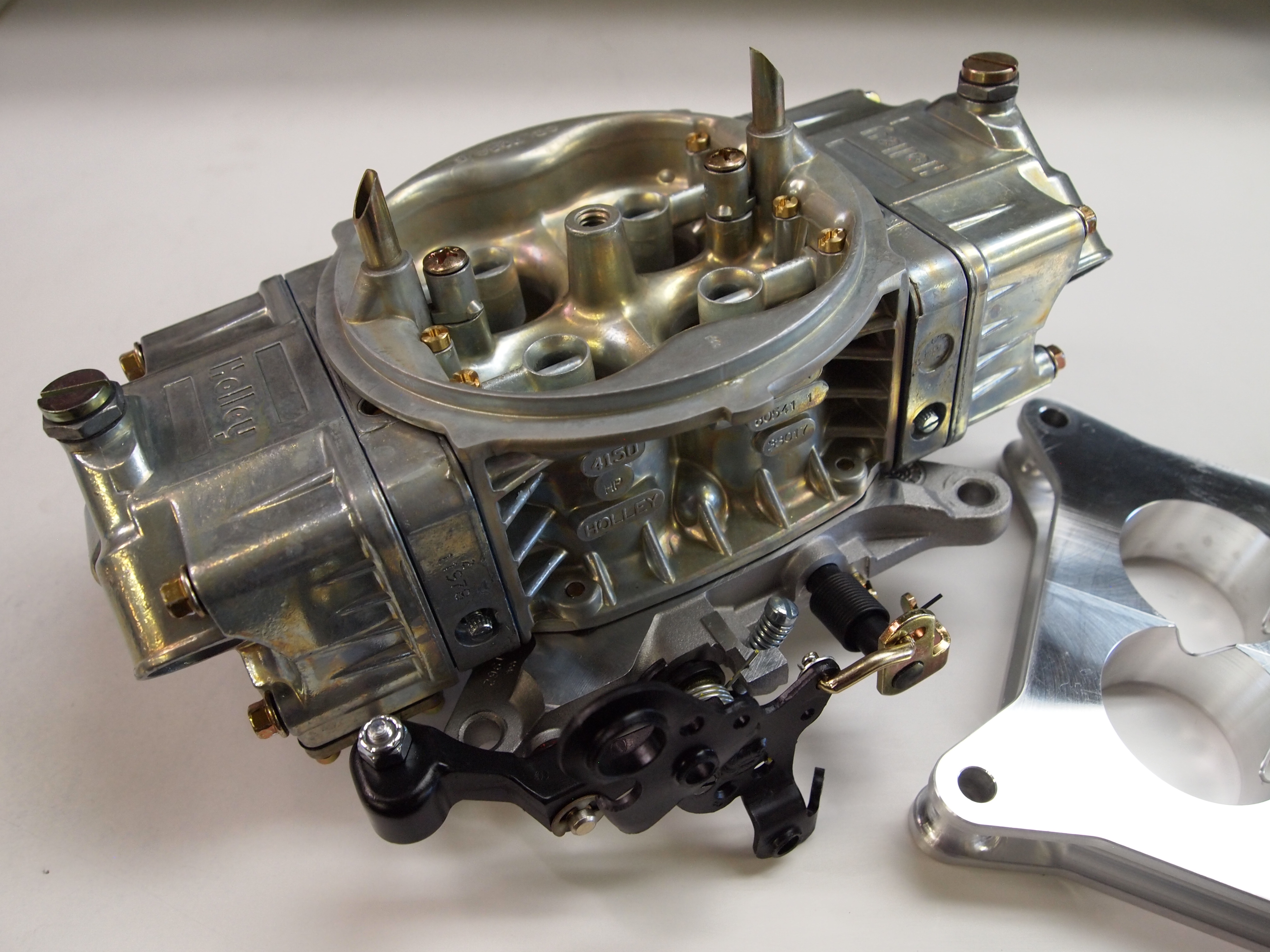

Holley 80541 650 HP Carburetor

Quickly becoming one of circle track’s most popular carburetor, this 650 HP was brought into racing through the crate engine programs. Now, it is also being used in “built engine” higher horsepower applications. The rule makers’ idea behind the choice of this carburetor was that the 650 HP would supply the engine with all the airflow necessary and yet would not lend itself to the high cost of tweaking (cheating) like smaller carburetors tend to do. Some folks even stated early on in the advent of crate engine racing that there were no improvements that could be made to this carburetor when it was applied to lower horsepower crate engines.

Motivated by this challenge, VDL Fuel Systems went to work on perfecting the fuel curve and fuel distribution. What we found was a surprising 10 – 15 horsepower gain and predictable consistency. VDL Fuel Systems then took this carburetor to the track and solved the drivability issues, resulting in superior performance on the dyno and on the track.

The results were immediate with acceptance by rules committees and domination in winners’ circles. The purchase of a VDL 650 HP gets you “out of the box” and into victory lane.

ALL HOLLEY 80541 650 HP CARBURETORS ARE NOW BUILT WITH CAST ALUMINUM PIECES. THE NEW LIST NUMBER IS 80541-3.

SAME GREAT VDL PERFORMANCE AND 5 POUNDS LIGHTER!

Application: Holley 80541 $1200 all crates and DIRT 358s

- Built specific to each different crate engine or DIRT 358s with unique fuel curves

- Settings adjusted for each different class of car

- Will remain “stock appearing” if necessary

- Each stock Holley component modified to VDL specs

- Will pass every tech tool

- Built with the stock progressive link or a 1:1 link

Application: Holley 80541 $1200 Pro Late Models

- Built specific for Pro Late Model crates with unique fuel curves for each crate engine

- 1:1 link with NASCAR throttle stop installed for crisper throttle response

- Each stock Holley component modified to VDL specs

- Will pass every tech tool

Application: Holley 80541 $1200 NLMS

- Built specific for NLMS crates with unique fuel curves for each crate engine

- Booster epoxy and safety wire installed as mandated by NLMS rules

- Each stock Holley component modified to VDL specs

- Will pass every tech tool

Application: Holley 80541 on ethanol $1350 Call for details

Holley 4777 650 cfm Carburetor

This carburetor was developed specifically for the DIRT Sportsman Modified series. While this carburetor is not as restrictive as many of the other “straight leg” booster carburetors, it is power limiting. When the rules were written, the intent of the restrictive carburetor was (1) to slow the cars down and (2) to equalize the performance of the engines. They did accomplish slowing the cars down, but VDL Fuel Systems has done a superior job of keeping the performance unequal!

When a carburetor is improperly sized to the engine, there are a variety of problems that arise. The air/fuel circuitry was not designed for the air speed and booster signal of this application. What results is a fuel curve that is too lean on the bottom and too rich on the top. This is exactly the opposite from what the fuel curve should look like. VDL Fuel Systems has done extensive dyno and track testing to recalibrate the air/fuel circuitry, accelerator pump circuit, and idle circuit, producing optimum torque, horsepower, and drivability.

Application: Holley 4777 – old style with choke horn $1250

- Venturis blueprinted to maximum sizing

- Air/fuel circuitry calibrated

- Idle circuit calibrated

- Accelerator pump circuit tailored to application

- Welded throttle shaft

- Base plate matched to main body

- Booster calibrated, sized, and precision installed

- All parts vibratory polished for enhanced airflow

ATTENTION CRATE RACERS:

Please read our crate tech tips available on the home page to get the most out of your crate engine and carburetor.

Tuning Tips for your 650 Carburetor

Float Level – The aluminum bowl with the sight glass of the 80541-3 carburetor requires the float to be set with the fuel line across the center of the glass. (The fuel level for the 80541-1 and 80541-2 zinc carburetors should be set at the bottom of the sight hole so that you have to jostle the car to get the fuel to come out the sight hole when running.) We set the floats to the correct setting on the bench during assembly; but fuel pressure dictates fuel level. Therefore you must check this setting when you first install the carburetor. If the floats are set too high the carburetor will be too rich at low rpm and/or part throttle conditions. You will particularly notice this when coming off the corners. It should be noted that at a no-load situation, such as in the pits setting the timing, the carburetor will always have a slight rich condition at probably 3000 rpm. This is due to the fact that the strong booster signal and the fuel metering that enables us to make good torque numbers is pulling a lot of fuel in at this rpm/vacuum. At the same time there is no way to burn the fuel because there is no load, and the engine will flutter. Finally, after setting the floats, always give the carburetor time to burn off enough fuel to reopen the needle/seat so that your new setting is really what you are seeing. Many times people lower the float too much because they haven’t waited a sufficient amount of time for the fuel to burn off and for the new setting to take.

Throttle Blade Adjustment – The throttle blades should be set at an rpm that is as low as possible to keep from pulling through the high speed circuit/the boosters at idle. Special attention should be taken to ensure that the primary and the secondary throttle blades are always adjusted as low as possible, with the primary never being more than 1/2 round open. If you should lose your settings just back them both completely off, put 1/2 round in the primary and 1/2 round in the secondary, and start there.

Idle Mixture Screws – Always adjust the 4 idle mixture screws evenly. The settings on all 4 should be the same. One round out is the original setting. (Built engines will require 1 ½ turns out.) If for some reason your engine absolutely needs a different setting on one side or one corner you can just about bet something is wrong with the engine causing it to have a different signal/vacuum on that side/corner.

Fuel Pressure – 6 to 7 pounds. You should absolutely know what your fuel pressure is! Many racers have no clue what their fuel pressure is, and they chase engine problems for weeks when a simple fuel pressure gauge would have indicated the problem straight away.

Vent Tube Clearance – You must have at least ¾” clearance above the vent tubes. It is ok to lower the vent tubes if absolutely necessary, but you will begin to run the risk of fuel spilling over in the turns if you are not careful.

Pump Circuit Tuning – Because of the differences in track conditions and driving styles you may need to adjust the pump circuit, i.e. pump arm to correct “off corner” stumbling issues. If an engine stumbles two or three times after the driver steps into the throttle, this usually indicates too much fuel and can be corrected by adjusting slack in the pump arm.

The 604, 603, and 602 crate engines can require different pump circuit settings due to the intake manifold designs and varying efficiencies of the engines. Typically for the 604 crate engine, we will adjust the secondary pump arm to full slack, taking all of the secondary pump shot out of the set-up. On the 602 and 603, we have found the engine needs a little of the secondary pump shot to eliminate a stumble off-corner so we start at 3 turns of slack in the secondary pump arm. Depending on driving styles and engine parameters, the secondary pump arm may need to be adjusted with more or less slack. So, if you are chasing an off-corner stumble and all the settings are as we have discussed above, then you can adjust the secondary pump arm to increase or decrease the pump shot and tune for optimal performance.