The function of the carburetor spacer is threefold: (1) to adapt the carburetor to the manifold when the manifold bolt pattern does not match the carburetor, (2) to increase the plenum volume under the carburetor, and (3) to distribute the air/fuel mixture in an efficient and equal manner to each manifold runner.

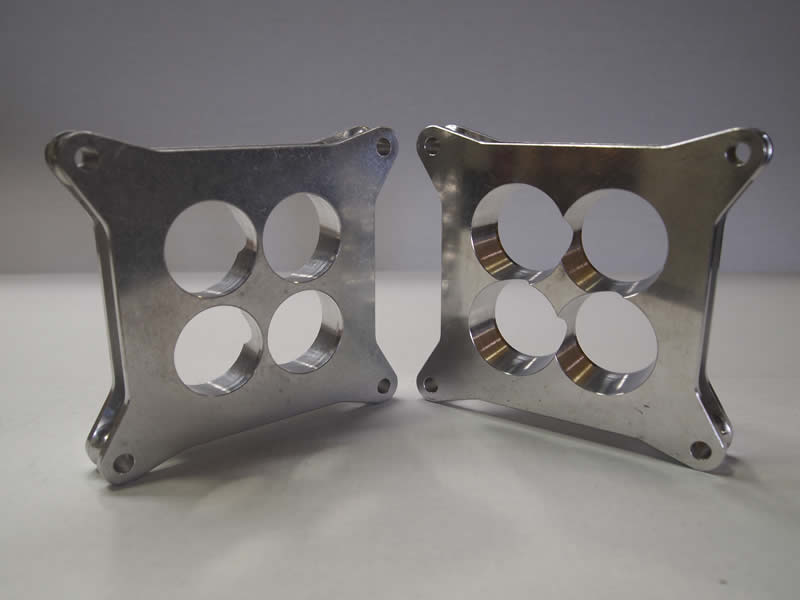

These CNC-machined billet aluminum spacers have been designed with each of these parameters in mind. There are many spacers available that properly handle the first two criteria with variable bolt patterns and spacer heights, but few properly handle the air/fuel mixture so that it maintains maximum flow and equal distribution. VDL Fuel Systems started with a blank sheet of paper and, with basic engineering principles, designed the proper taper to maximize air flow. Resisting the urge to “look trick”, we stuck to the fundamentals that have long been established for proper flow control concerning increasing volume (carburetor bore size to manifold plenum size) versus laminar flow (maintaining boundary layer consistency). The result was a tapered design with a maximum taper to optimize flow volume while resisting the natural tendency for turbulence through boundary layer separation. While at first glance these tapered spacers don’t appeal to the senses as much as the “trick spacers”, dyno testing has proven consistent increases in peak torque and horsepower. We have no reptiles or Dairy Queen swirls – proving once again that “Tricks are for Kids!”

Available in 1″ billet aluminum:

- 2 barrel carburetor to 4 barrel manifold with tapered bore $150

- slotted corners to adjust position on the manifold

- 4 barrel carburetor to 4 barrel manifold with tapered bore, lightened $150

We do not have straight spacers in stock because “straight is straight” and this design is so readily available; however, we strongly recommend using a spacer that is billet aluminum as opposed to phenolic or plastic which can warp with heat and moisture.